Developing the circular economy

IFSTTAR is participating in the development of the circular construction economy by proposing alternative materials that are innovative or recycled, particularly due to the recycling of deconstruction materials and the in-situ recycling of soils, particularly in urban areas.

Four projects on these topics came to an end in 2017: BioRePavation, RECYBETON, the reuse of urban soils in road construction and Terra-Nova.

Projet BioRePavation

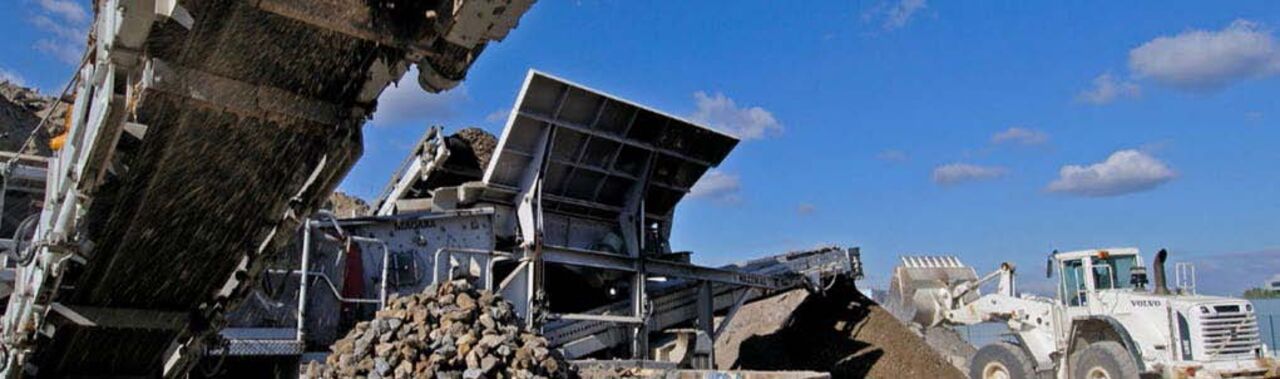

BioRePavation (November 1, 2015 - April 30, 2018) set out to make pavements more environmentally friendly. The idea behind the project was to use "biosourced" binders while reusing high proportions of materials recovered from end-of-life roads. BioRePavation was led by IFSTTAR and brought together 6 European and American partners from the industrial and public research sectors. The project received €1.3 million in European funding.

Three innovative solutions based on biosourced materials and recycled mixes (50%) were tested. Some were close to being launched on the market, while others were at an earlier stage of development. The evaluation was carried out mainly through a full-scale test using IFSTTAR's circular test track. This large facility can replicate 10 years of truck traffic in one month. The experimental pavements were instrumented with a large number of sensors to monitor their behaviour: deformation, temperature, humidity, etc. A life cycle analysis and laboratory measurements of fumes emissions were also carried out.

The results from this full-scale test are outstanding. After 30 months of teamwork formulating materials, designing structures and applying over a million loads, it was proven that the proposed concept is not only industrially feasible but also provides very durable materials. Indeed, BioRePavation's innovative mixes perform better than the best material used in Europe (EME2). After application of the equivalent of 1.9 million reference French axle loads (130 kN), some sections have not yet exhibited any distress, which will lead IFSTTAR to continue loading beyond 1.9 million load applications.

![[Translate to Anglais:] BioRePavation [Translate to Anglais:] BioRePavation_img](/fileadmin/_processed_/d/d/csm_Biorepavation_b6d2899467.jpg)

![[Translate to Anglais:] BioRePavation [Translate to Anglais:] BioRePavation_img](/fileadmin/_processed_/f/7/csm_BioRePavation_3524ff7da4.png)

The RECYBETON National Project: recycling of concrete

The RECYBETON National Project has been completed. Its aim was to boost the recycling of concrete by analysing the compatibility of its components and promoting their use at construction sites. With the participation of 43 partners and a budget of €4.8 million, this project was led by IREX with the support of MTES and had as its objective the use as constituents of new concrete of all the aggregates obtained from deconstruction concretes, including the fine fraction. Thus, ultimately, all the materials obtained from deconstruction would be recycled as raw materials in cement production. Through the MAST department's MIT and GPEM laboratories, IFSTTAR has been heavily involved in this large-scale project, both for the recycling processes and the characterisation of the concretes obtained. Research conducted in the framework of RECYBETON has been deployed in the ANR project ECOREB (ECOconstruction for Concrete Recycling) in the context of 3 themes: water and recycled materials, the study of the mechanical behaviour of materials derived from recycling, and the durability of such materials. A day during which the results of the National Project were presented was held on 9 March 2017 and the scientific results will be shared at the "4th International Conference Progress of recycling in built Environment" on 11 and 12 October 2018 in Lisbon and during the ECOREB day on 15 May 2018.

The re-use of urban soils in road construction

Funded by the FNTP (a partnership between Eiffage and RAZEL BEC), a project on the reuse of urban soils came to an end in 2017 with the defence of Katia Bellagh's thesis (IFSTTAR/ESITC). An environmentally-friendly characterisation method, derived from that used to sort aggregates, was proposed in addition to the range of geotechnical tests in order to describe the shared properties of these soils. These operational conclusions will inform the drafting of a technical guide for the re-use of excavated soils with low contamination levels that covers both geotechnical and environmental requirements (the reuse methodology and assistance in defining appropriate limits). Two urban soils from the Paris region, with varied histories and from distant sampling sites, were compared and found to be surprisingly similar in their geotechnical class, mineralogical nature and chemical composition.

The research also showed that the contaminants present in the tested urban soils had little or no effect on their geotechnical behaviour. The soils were deemed acceptable for use as backfill or as a capping layer from the point of view of mechanical performance or suitability tests for treatment with lime (1%) or hydraulic binders (5%). The factors that prevent the reuse of soils on environmental grounds have been shown to be the presence of sulphates with fluorides and antimony (with the soluble fraction). Finally, leaching, percolation or monolithic immersion tests revealed that treatment with lime or hydraulic binders has an impact on the release of pollutants in the soil - some elements seem to be stabilized while others are released in greater quantities.

Joint research between IFSTTAR and CEREMA has also explored ways of recycling new materials and improving construction techniques, both for earthworks and building construction.

Terra-Nova: recycling new materials and improving construction techniques, both for earthworks and building construction

The results of the former ORSI Terra-Nova, which is a major research partnership between IFSTTAR and CEREMA, allows better practical exploitation of local marginal materials (soils that are too dry, dredging sediments, demolition materials, slightly contaminated urban soils or borderline soils) and encourages their reuse in currently limited settings by defining appropriate rules, as well as an analysis framework and methods.

In terms of structures, the Terra-Nova research project supplements the existing rules of best design practice and lays down certain design rules in the following areas of earth constructions:

- embankment slopes,

- fill adjacent to engineering structures,

- infrastructure subgrades in general

- adaptation of earthworking techniques to extreme climatic conditions,

- earth construction for buildings,

- urban soils.

An event was held to present the results on 28 May 2018 at IFSTTAR’s Nantes site.

during manufacture and speeds up the process.

© Erwan Hamard / IFSTTAR-MAST-GPEM

![[Translate to Anglais:] RECYBETON [Translate to Anglais:] RECYBETON_img](/fileadmin/_processed_/2/f/csm_recybeton_90e5a8bba1.png)