New transport infrastructure and energy production

Faced with the challenges of new forms of mobility, innovation is emerging in the infrastructure for transport and energy production and storage.

With the support of the European Commission, the CEDR and the FEHRL, a roadmap on the future of transport infrastructure has been developed within the framework of the FORx4 project (Forever Open Road, Rail, River and Runway), and more specifically the FOX and USE-IT projects, presenting a vision of the construction and adaptation of these infrastructures to future mobility, intermodality and climate change. Officially launched at TRA 2018 in Vienna, this roadmap proposes an intermodal R&D environment and ethos and research avenues for construction, testing, maintenance and recycling.

The FOX project: Forever Open infrastructure across all transport modes – Road map

The goal of the FOX projectis to develop an intermodal R&D environment and ethos to meet future transport and connectivity requirements for people and goods. This project addresses the different phases of the transport infrastructure life cycle, namely construction, testing, maintenance and the end of the life of materials (recycling). It deals with road, airport, rail and waterway infrastructure. Initially, FOX built a network of researchers and practitioners working on the different modes of transport, sharing their views and a common technical ethos. In the second phase, the project developed roadmaps to encourage innovation and the development of intermodal research, as well as to assess its short-, medium- and long-term potential. The project began with a review of the current state of knowledge and advanced practices for all aspects of the transportation infrastructure life cycle. It aimed to highlight the problems associated with each method or technology. The most promising methods for intermodal development were then identified and analysed. The third step was to develop a roadmap for future research, development and implementation initiatives across the four transport modes.

The 5th Generation Road

The 5th Generation Road (R5G) is made up of technological building blocks preparing for the future, which takes in positive energy, thermal or electric, instrumented and communicating roads... IFSTTAR is contributing to the development and construction of the R5G demonstrators for the I-Street project, responding to the call for projects of the "Road to the Future" Future Investments Programme (PIA) financed by ADEME, as part of a consortium with Eiffage and TOTAL. Three large demonstrators are currently deployed: on the IFSTTAR circular test track in Nantes (2017), in the framework of the Sense-City EQUIPEX (2017) and on the RD 199 county road in Marne-La-Vallée (ongoing). What is special about this new generation of roads is the way the built environment and the road infrastructure interface with each other in order to optimize the system for the benefit of urban users. These demonstrators help optimize energy interchanges between roads and nearby buildings, mitigate noise and pollution, reduce the heat island effect, and manage stormwater. In addition, R5G is diversifying into regional projects with the deployment of innovative energy and mobility solutions.

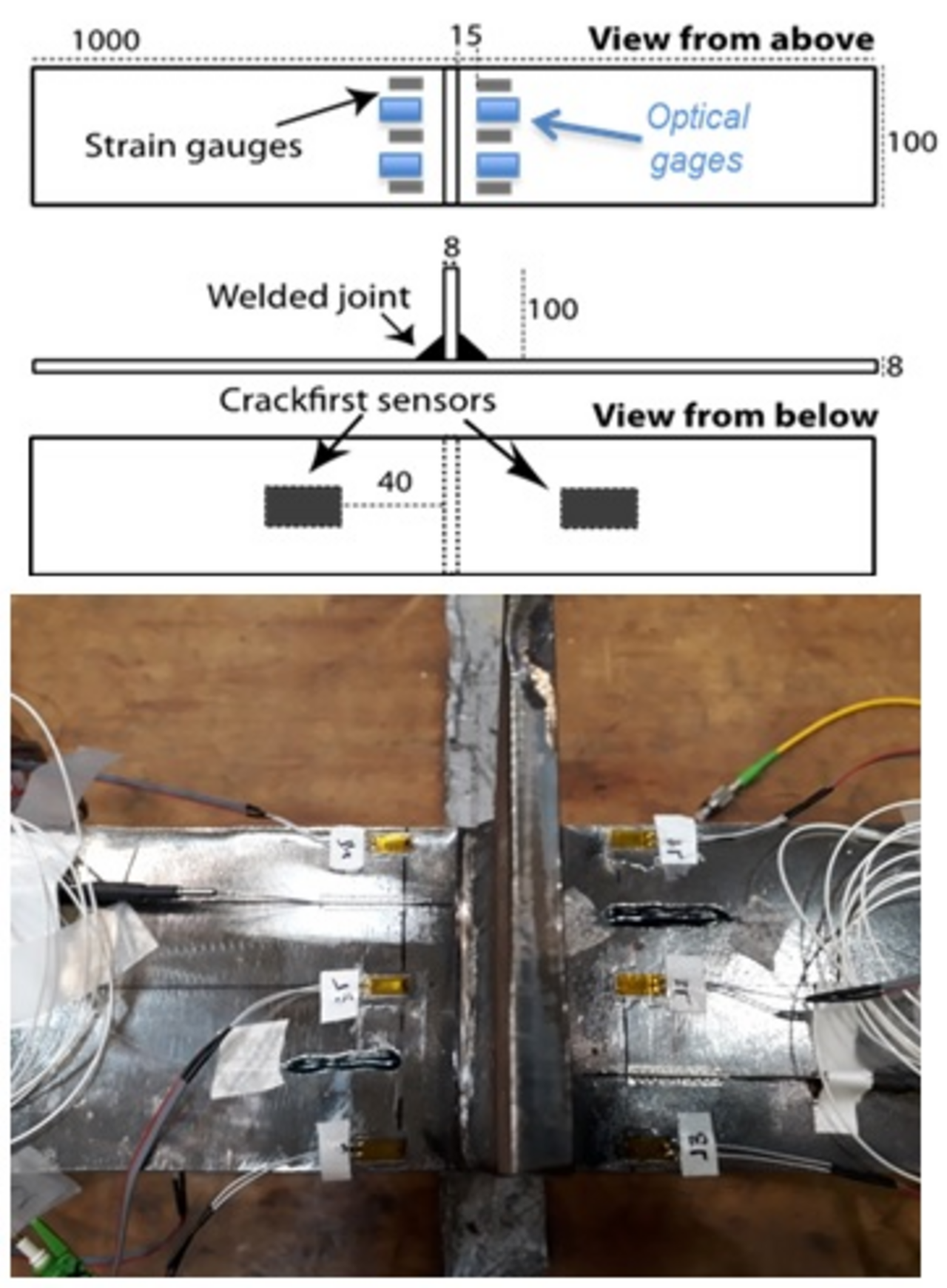

The SURFFEOL project: the monitoring and reliability of wind turbine foundations (IFSTTAR/ Pays de Loire Region, 2014-2017)

Via the SURFFEOL project led by Ecole Centrale Nantes, the Institute's expertise regarding materials, structures, geotechnics and components and systems has been applied to assist in the design and construction of renewable energy production and storage infrastructure. Supported by the Pays de la Loire Region, this project focused on the instrumentation and testing of civil engineering structures for marine renewable energy and offshore wind turbines. It aimed to implement systems and methods to improve the durability and reliability of offshore wind turbine foundations. In the course of SURFFEOL, various corrosion monitoring systems and anti-corrosion processes underwent laboratory evaluation (in particular, using an accelerated tidal device). Laboratory evaluation of several fatigue monitoring techniques (fatigue gauge, optical fibre) was also carried out. These methods and techniques have been comprehensively validated using an offshore demonstrator installed off Le Croisic. Instrumented coupons and test pieces were used to monitor corrosion and fatigue mechanisms on the demonstrator with the possibility of remote polling via a dedicated web portal. This project is aimed at sharing knowledge with the RME (Renewable Marine Energy) community through international events (EWSHM: European Workshop on Structural Health Monitoring) and several national events. SURFFEOL was the opportunity to take on Mélanie Denecker for 12 months as a post-doctoral researcher.

The cable fatigue test bench finds a finds a second youth

The cable fatigue test bench is able to perform full-scale tests on civil engineering cables or tubular engineering structures. This type of test is essential in order to validate any innovative technical solution and make sure of the product's durability/integrity under real operating constraints.

This facility is the only one of its kind in France, and one of only three in the world. It was acquired by IFSTTAR in 1989 and completely refurbished in 2017. In the past it was used exclusively for fatigue tests on the cables and anchorages of prestressed, suspension and cable-stayed bridges to certify their stay systems for use in France and abroad (the Rion-Antirion and Millau bridges, etc.), but it is now also used for offshore installations. New partners are interested in the full-scale behaviour of technical solutions for offshore operations or the prevention of seismic risks.

The cable and its anchorages are placed under static tension and then subjected to cyclic force. The forces applied vary from a few percent to 80% of the breaking force. Acoustic sensors are used to detect and locate any failures that occur during the test.

The latest changes to the facility enable complex fatigue tests to be carried out by combining tensile and bending forces.

The cable fatigue test bench in a few figures:

- static loading: 3 hydraulic jacks, max load 24 000 kN (kilonewtons)

- bending loading: 1 hydraulic jack, 100 mm stroke, max load 250 kN

IFSTTAR's research using this "outstanding facility" has led to a better understanding of the ageing of civil engineering cables and to solutions for forecasting or preventing the resulting deterioration.

In the years to come, the cable fatigue test bench will be used for a considerably wider range of applications that will, in particular, include offshore-related research topics such as increasing the safety of oil recovery installations or problems associated with the exploitation of MRE, a field with very high economic stakes.

In this context, IFSTTAR's SMC laboratory - which runs the test bench - has a major role to play in providing R&D projects with experimental equipment that is almost unique in the world. The time savings in developing innovative solutions through full-scale accelerated testing can be crucial in the global context of scientific, technical and economic competition for marine energy.

![[Translate to Anglais:] USEITFOX [Translate to Anglais:] USEITFOX_img](/fileadmin/_processed_/8/0/csm_useitfox_ac8d2095ec.jpeg)